In the civilian world of actually flying aircraft from Point A to Point B the traffic pattern is a bit of an afterthought. You get around the pattern just by pointing the nose where you want to go and you deal with unexpected events as they happen, no big deal.

— James Albright

Updated:

2012-04-14

In the world of military aviation you tend to be in the business of training pilots and you need to pack as much into each pattern as is possible without bending anything. You got pretty good at it. Are there lessons for the civilian world? You bet. We can do a better job . . .

. . . bringing science to an art.

In 1986 the Air Force only had four Boeing 747s so they contracted training to the cheapest bidder with instructions to bring the pilot up to airline captain standards. For me, that meant enrolling in the United Airlines Boeing 747 Captain’s Course, with twenty United captains, a month of simulator training, passing an airline check in the simulator, and passing an FAA Airline Transport Rating evaluation in the airplane. All that happened and the training was the best I had ever been through. Flying a United Boeing 747 and departing from the very gate I had used as a passenger many times in San Francisco was thrilling, no doubt about it. But none of it prepared me for what was to come back in the squadron.

The airline solution to the landing pattern was very relaxed, no surprises, and everything done methodically the same time every time. There was a finite list of airports and pilots trained for each airport by name, often in a simulator, before they were considered capable of using that airport in the future. There is a lot to be said for that method.

The Air Force solution was to cram that very big airplane into some very small runways and crowded airspace, do it at any airport without prior notice, no prior airport-specific training, and to do it right the first time, every time. I had some learning to do.

The speeds were similar to the Boeing 707 I had been flying for five years; in fact many of the speeds were actually lower. The problem wasn’t the airplane, it was the operation. We flew the larger airplane in less airspace and our tolerances were tighter. The seasoned pros in the unit had learned to adapt with experience and skill. Lacking both, I needed a better handle on what the airplane could do before I could coax it to follow my commands.

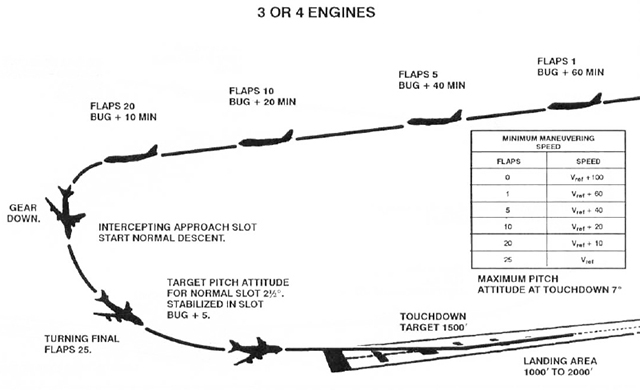

Everything the airplane did in the pattern was based on full flap reference speed, VREF. Unlike the Boeing 707, there were not set pattern speeds. I suppose it was because the weight could vary so wildly. A full fuel load on our 747-200’s was 303,000 pounds and the airplane was typically landed with just 25,000 pounds. A hundred people could change the weight another 20,000 pounds. That variation itself exceeded the Boeing 707’s gross weight. I decided I needed a pattern diagram that made allowance for two conditions: one for very light weights and one for max landing weight, which was 630,000 lbs.

VREF for the lightest possible landing weight, I knew from my United Airlines check ride, was 109 knots. But that was a Boeing 747-100, a smaller version, built for carrying lots of people with nothing but empty seats on board. Our aircraft was a Boeing 747-200 with far fewer seats and a lot of heavy electronic equipment. The lowest VREF I had seen in the traffic pattern was 120 knots, a good, even (2 nautical miles per minute) number.

The highest VREF I would see on a routine basis would be for maximum landing weight. That looked like about 150 knots. While not an even number for turn radius calculations (2-1/2 nautical miles per minute), it wasn’t bad.

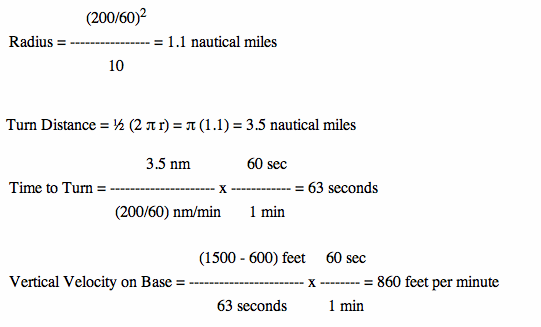

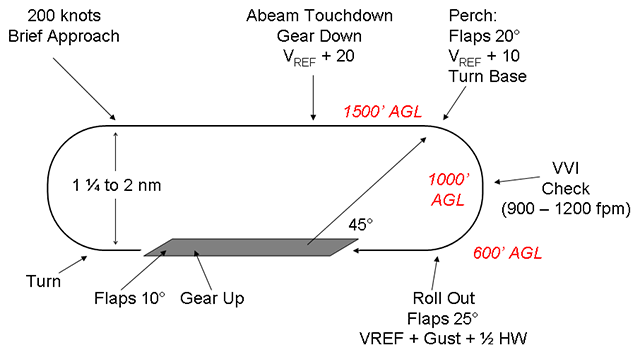

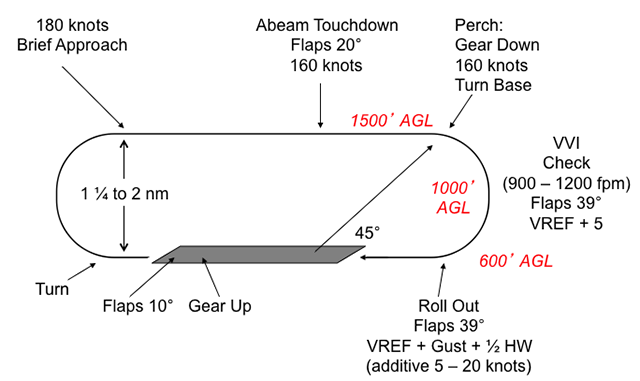

These speeds, VREF, were for 25 degrees of flaps and the airplane slowed on final approach for landing. The takeoff was normally made at 10 degrees of flaps and a higher speed, the turn to downwind was usually done while accelerating to about 200 knots.

Unlike the doctrine we had in my earlier Air Force airplanes, the Boeing 747 pattern was a continuous oval with no periods to roll wings level to check for traffic and catch one’s breath. The math behind an oval is easy, it’s just half a 2πr circle after all, but getting the turn radius for a circle with continuously changing speed would be difficult.

Using the 10° flaps speed for the initial turn from the runway to downwind meant the radius would be based on VREF + 20, which meant anywhere from 140 knots to 170 knots, depending on weight. Variations in pilot technique could increase the range to 200 knots by the time the airplane had rolled out on downwind.

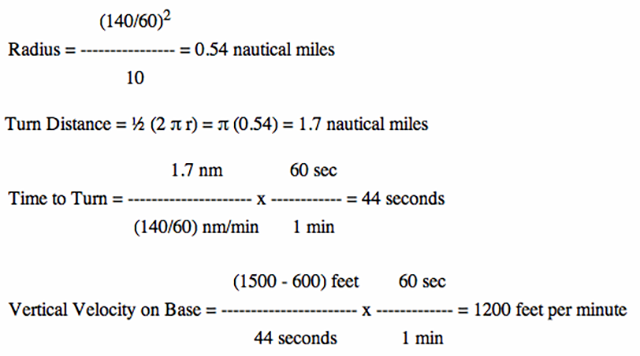

Like we did in the Boeing 707, the standard visual pattern was flown at 1,500 feet above the runway. The turn to base, “perch” as we called it in the Air Force, was on a 45 degree angle to the touchdown zone, and roll out was 2 nautical miles from touchdown at 600 feet.

So the numbers became clear.

For the lightweight pattern:

For the heavyweight pattern:

As expected, the pattern was tighter than what we flew in the Boeing 707 and things happened faster. That was confirmed anecdotally every time we shared the pattern with the bases EC-135C’s, a cousin to the EC-135J’s back in Hawaii. Our patterns were always tighter.

What I didn’t expect was the increased vertical velocity of the lightweight pattern. The airplane is moving slower through the air but the pattern was so small it was going pretty fast downhill.

The exercise of diagramming the visual pattern was helpful and made adapting to the faster pace and different procedural steps easier. I completed a diagram for every variation in flap settings, four-engines versus three-engines, and every possible instrument approach variation.

Postscript

Thirty years later, I continue the practice of diagramming every pattern and approach variation. I’ve noticed that I seldom refer to the diagrams once they are drawn, but the practice of making meticulous diagrams helps cement the procedures into gray matter. And that is a good thing.