As an engineer, EPR is simply a ratio of pressures, simple. As a pilot, Engine Pressure Ratio is FM, you know, magic. It very rarely is what your books tell you, the ratio of the pressure leaving the engine divided by the pressure entering the engine. About half the airplanes in my logbook used EPR as the primary indication of engine thrust, but of those I think only one used the classical definition of EPR. The rest used something else that was convenient, but certainly not exit pressure divided by inlet pressure.

— James Albright

Updated:

2012-08-01

If you are a pilot, all you need to understand is that EPR is a way of allowing you to measure thrust for a Control and Performance Technique. If you want to know what EPR really means, read on . . .

1

The NASA / aero engineering explanation

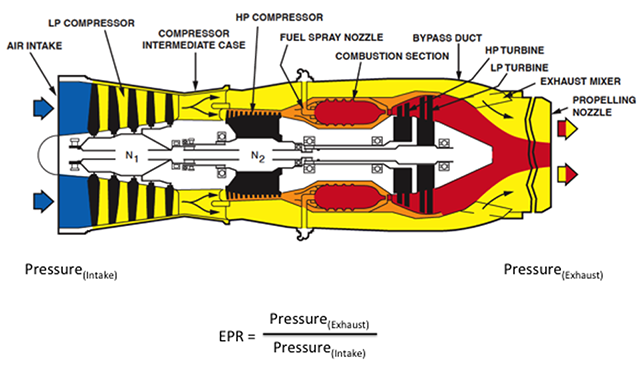

Engine Pressure Ratio, from https://www.grc.nasa.gov/WWW/K-12/airplane/epr.html

The purest way to measure an engine's thrust is to mount it on a stand that measures force — think of a bathroom scale turned on its side — add some fuel and ignition and read the scale. They do that with the engine in the design and test phases, but that is hardly practical when the thing is mounted to an airplane.

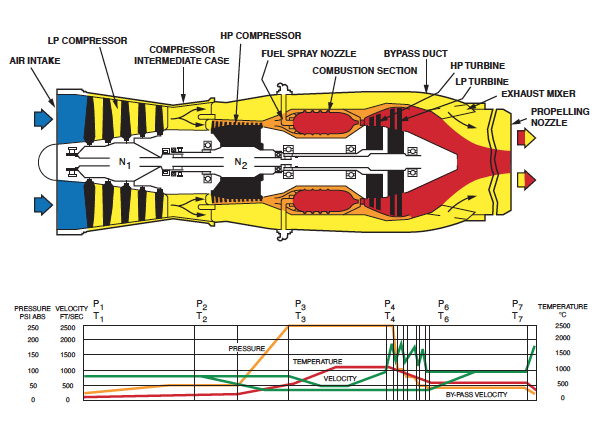

You can also stick a pressure probe in the inlet to measure what the engineer typically calls P2, and another in the aft end of the engine to measure P8. The basic definition is that you can measure an engine's thrust by dividing the pressure at the tail pipe (pt8 in the drawing) by the pressure and the inlet (pt2) to come up with an Engine Pressure Ratio suitable for viewing in the cockpit as an instantaneous representation of thrust.

Does the pilot really need EPR to fly the airplane? No, but some indication of engine thrust is key to flying the airplane precisely in what professional aviators call the Control and Performance technique.

2

A few examples

(From my sordid past.)

T-37 example (RPM)

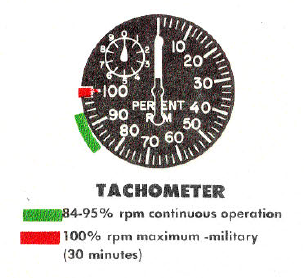

Tachometer, from Technical Order 1T-37B-1, pg. 5-2.

In many airplanes engine speed is measured directly in terms of revolutions per minute, RPM, and that is present to the pilot as a percentage of its maximum rated RPM, such as with the T-37.

While the RPM was rarely a good measure of differences in thrust — a 2 percent change near idle was hardly noticeable; a 2 percent change nearer the maximum produced a big change — it was good enough.

T-38 example (RPM)

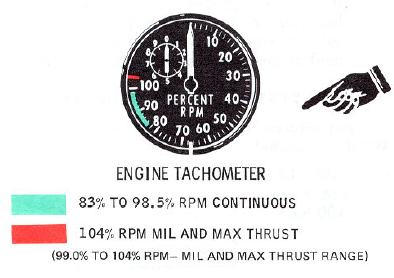

Engine Tachometer, from Technical Order 1T-38A/B-1, pg. 5-2.

The T-38 also used RPM but needed additional indications to reflect the performance of its after burning engine. But pilots primarily relied on RPM.

KC-135A example (EPR)

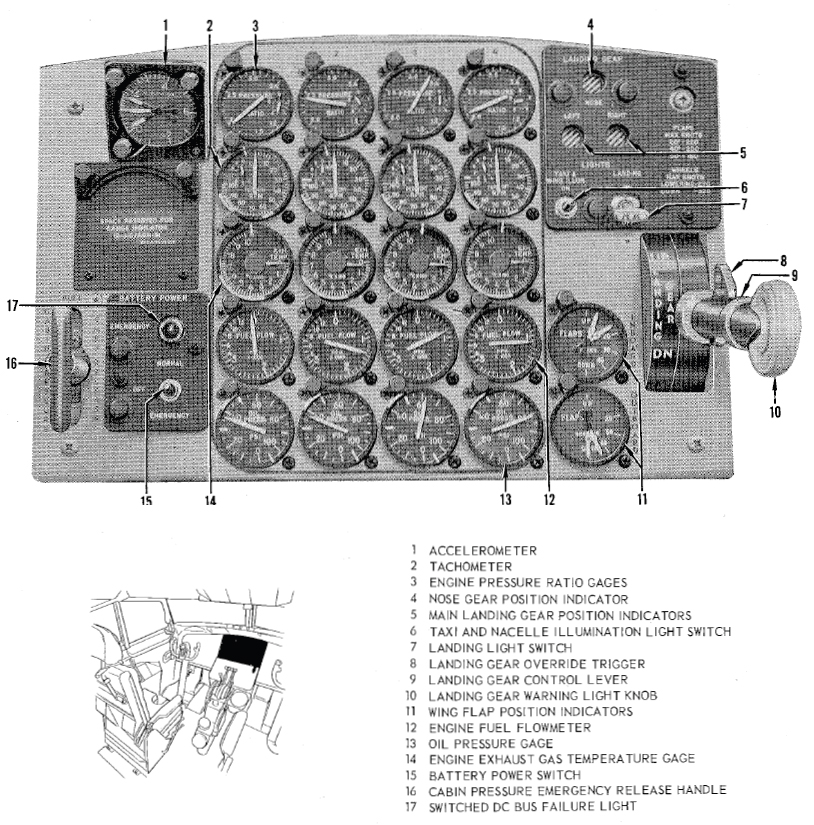

Pilot's Center Instrument Panel, from Technical Order 1C-135(K)A-1, pg. 1-14

The KC-135A used RPM for basic limitations, but takeoff thrust was measured in EPR using probes just like in the basic definition: one in front and one in back.

The engines were grossly underpowered and the EPR proved it: 1.83 was takeoff rated thrust.

B-707 example (bypassed EPR)

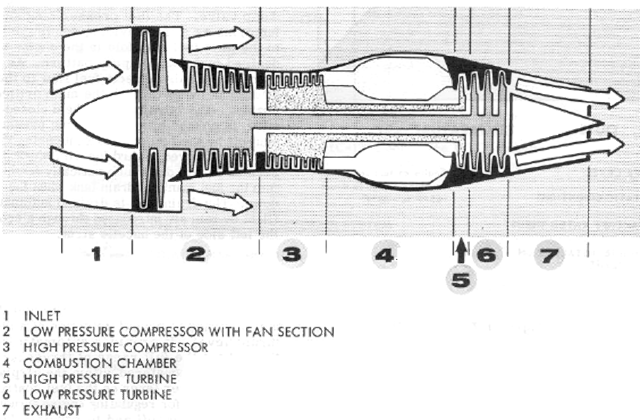

Engine Diagram, from Technical Order 1C-135(E)C-1, pg. 1-9.

The TF-33 engine on our Boeing 707's, while not water injected, still measured EPR the same way: a probe in front and a probe in back, four gauges up front.

There was a difference, however. Some of the air from the front compressor bypassed the rest of the engine completely. This gave us more thrust, as if from a propeller, but that thrust wasn't measured.

EPR was starting to become a "representation of thrust," as opposed to a true measure.

Next up for me was this . . .

Boeing 747 example (RPM)

The four GE CF-6 engines are marvels of technology, each producing over 65,000 lbs. of thrust with an efficiency unheard of at the time. EPR? They didn't use engine pressure ratio at all, all power changes were made using RPM.

3

Gulfstreams and EPR

What follows is a discussion of a few of the Gulfstreams I've flown, but not all. The explanation can get muddy, but for these, here it is.

Gulfstream II/III (Spey)

Engine Diagram, from Technical Order 1C-20B-1, pg. 1-14.

Though I suspect the manuals were wrong, in the GIII, EPR was supposed to be just like it says in Jet Engine 101:

[Technical Order 1C-20B-1, pg. 1-22.] An engine pressure ratio (EPR) indicator for each engine is installed in the main instrument panel. The indicator provides an indication of engine power in the form of the ratio of exhaust total pressure (P7) to intake total pressure (P1).

The EPR gauge read P7 divided by P1, exhaust divided by inlet pressure. The takeoff power number tended to be around 2.5 but could be nearly 2.9 at some pressure altitudes and temperatures.

Gulfstream IV (Tay)

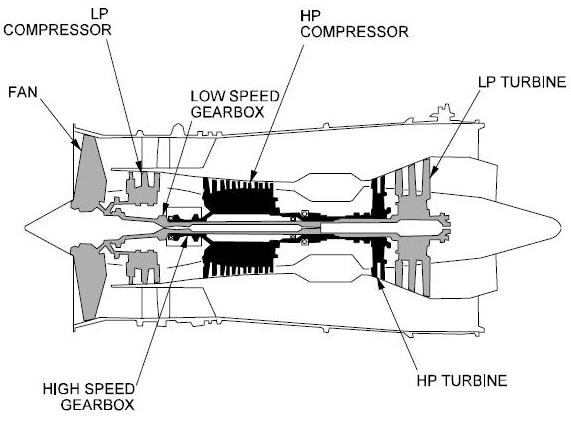

Powerplant General Arrangement, from Gulfstream GIV Operating Manual, § 2A-71-00, pg. 3.

In the GIV the operating manual says the engine has a pressure ratio of 16 to 1 and yet a typical takeoff EPR would be 1.7, clearly the Tay engine was not using exhaust divided by inlet pressure. The manual says EPR is the ratio of fan pressure to total intake pressure, perhaps proving the manual was written by a history major.

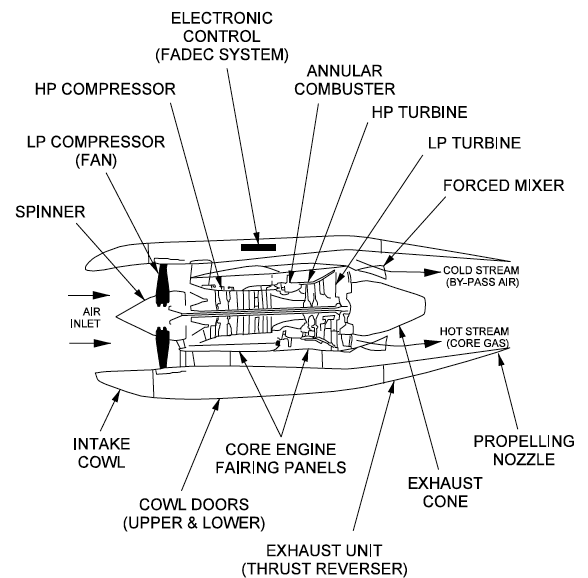

Gulfstream V/G550 (BR-710)

Powerplant General Arrangement, from Gulfstream GV Aircraft Operating Manual, § 2A-71-00, pg. 4.

The GV AOM [2A-77-10 ¶2.B.] says "EPR is used for thrust setting and is defined as the core exhaust total pressure (P50) divided by the engine inlet total pressure (P20)," which again agrees with the basic definition. But the BR-710 engine has a pressure ratio of 25.7 to 1 while typical takeoff EPR numbers rarely exceed 1.5. (So they want you to believe the GV has less thrust than a GIV?)

What Gulfstream EPR Really Means

It is no wonder there are generations of GIV and GV pilots who do not understand EPR. In a rare bit of clarity, the G550 operating manual sheds light on what EPR in the BR-710 actually means:

[Gulfstream G550 Aircraft Operating Manual, ¶2A-76-30] Since actual engine thrust can only be measured in a test facility, a surrogate measurement of thrust is used to manage engine power. The primary thrust setting reference on the Engine window(s) display is Engine Pressure Ratio (EPR). EPR is defined as the ratio of pressure sensed at the rear of the Low Pressure (LP) turbine to the pressure of the ambient atmosphere. The ratio measures the increase in ambient pressure generated by the action of the engine compressor stages and the energy of combustion driving the engine turbine stages. EPR is measured by the engine EEC and communicated to the Modular Avionics Units (MAUs) for use by the display systems. A typical EPR value for takeoff thrust at an airport near sea level on a standard day is one point five three (1.53). The EPR value is not a true indication of actual engine thrust since it does not measure the propulsive force generated by the LP fan stage air that effectively contributes a thrust component equivalent to some turbopropellers. EPR is used for thrust management because it most accurately measures the internal forces of the engine compressor and turbine stages.

Not to be outdone, the G450 compares ambient air pressure measured by the pitot/static system to the pressure within the engine aft bypass air duct:

- [Gulfstream G450 Maintenance Manual, § 77-11-00, pg. 1] EPR = P160 divided by P20. The EPR value is the ratio of the total fan duct pressure (P160), to the intake total pressure (P20). P160 is measured with four rakes installed at equal distance around the forward section of the bypass duct.

- [Gulfstream G450 Aircraft Operating Manual, § 2A-76-00, pg. 9] EPR is defined as the ratio of pressure sensed at the exit of the High Pressure (HP) compressor to the pressure of the ambient atmosphere as sampled within the engine bypass air duct. The ratio measures the increase in ambient pressure generated by the action of the engine compressor stages and the energy of combustion driving the engine turbine stages. EPR is measured by the engine EEC and communicated to the Modular Avionics Units (MAUs) for use by the display systems.

No matter where it comes from, Gulfstream admits what we really knew all along:

[Gulfstream G450 Aircraft Operating Manual, § 2A-76-00, pg. 9] The EPR value is not a true indication of actual engine thrust since it does not measure the propulsive force generated by the LP fan stage air that effectively contributes a thrust component equivalent to some turbopropellers. EPR is used for thrust management because it most accurately measures the internal forces of the engine compressor and turbine stages.

References

(Source material)

Gulfstream GIV Operating Manual, Revision 9, October 11, 2002

Gulfstream GV Aircraft Operating Manual, GAC-AC-GV-OPS-0002, Revision 30, May 13, 2008

Gulfstream G450 Aircraft Operating Manual, Revision 35, April 30, 2013.

Gulfstream G450 Maintenance Manual, Revision 18, Dec 12, 2013

Gulfstream G550 Aircraft Operating Manual, Revision 27, July 17, 2008.

Technical Order 1C-20B-1, C-20B Flight Manual, USAF Series, 1 November 2002

Technical Order 1C-135(E)C-1, EC-135C Flight Manual, USAF Series, 15 February 1966

Technical Order 1C-135(K)A-1, KC-135A Flight Manual, USAF Series, 25 April 1957

Technical Order 1T-37B-1, T-37B Flight Manual, USAF Series, 30 September 1959

Technical Order 1T-38A-1, T-38A/B Flight Manual, USAF Series, 1 July 1978

Please note: Gulfstream Aerospace Corporation has no affiliation or connection whatsoever with this website, and Gulfstream does not review, endorse, or approve any of the content included on the site. As a result, Gulfstream is not responsible or liable for your use of any materials or information obtained from this site.