Back in the days before Flight Management Systems (FMS), advanced flight directors, and Global Positioning Satellite systems, high performance aircraft pilots needed one of two things to survive: (a) a great deal of experience or (b) some math. When a new pilot came along with very little of (a) and no (b), we had a problem. If the pilot's peers didn't have any of the (b), the only solution was to grow the (a).

— James Albright

Updated:

2018-07-01

All that worked great if you had an environment where the pilot had a long grooming process and the system was built on that. But many of us latched onto the math and that proved to be better. We looked down our noses to those who still relied on the feel for things, saying they were too wedded to TLAR, doing things when "That Looks About Right." I was one of those down the nose lookers. But over the years I've come to realize there is indeed a place for TLAR.

So let's take a look at how things should look for various phases of flight, so as to be better armed for when things DLAR, don't look about right. The knowledge can save your life. It should go without saying that I don't have the right TLAR for your airplane. But I can help you find it.

1

The first rule of TLAR

The first rule of TLAR is that you do not talk about TLAR, unless you preface the rule with a little context. A rule for a Gulfstream GIV, for example, may not (probably does not) apply to a Cessna 172. By the same token, a rule for a Gulfstream GV may not apply to a GIV. Some of my TLAR might work for you, but it is vitally important that you find your own. You can do this. So, with that out of the way, let's look at helpful TLAR for the following situations.

2

Predeparture fuel

We used to joke in the T-37: "Nice job getting out of the spin, lieutenant. No how did you get into the spin in the first place?" This case study is one where the pilots didn't have a big picture idea of how much fuel they had because of a recent change in units. But even with that, they should have had an idea about what fuel load looks about right. So should you.

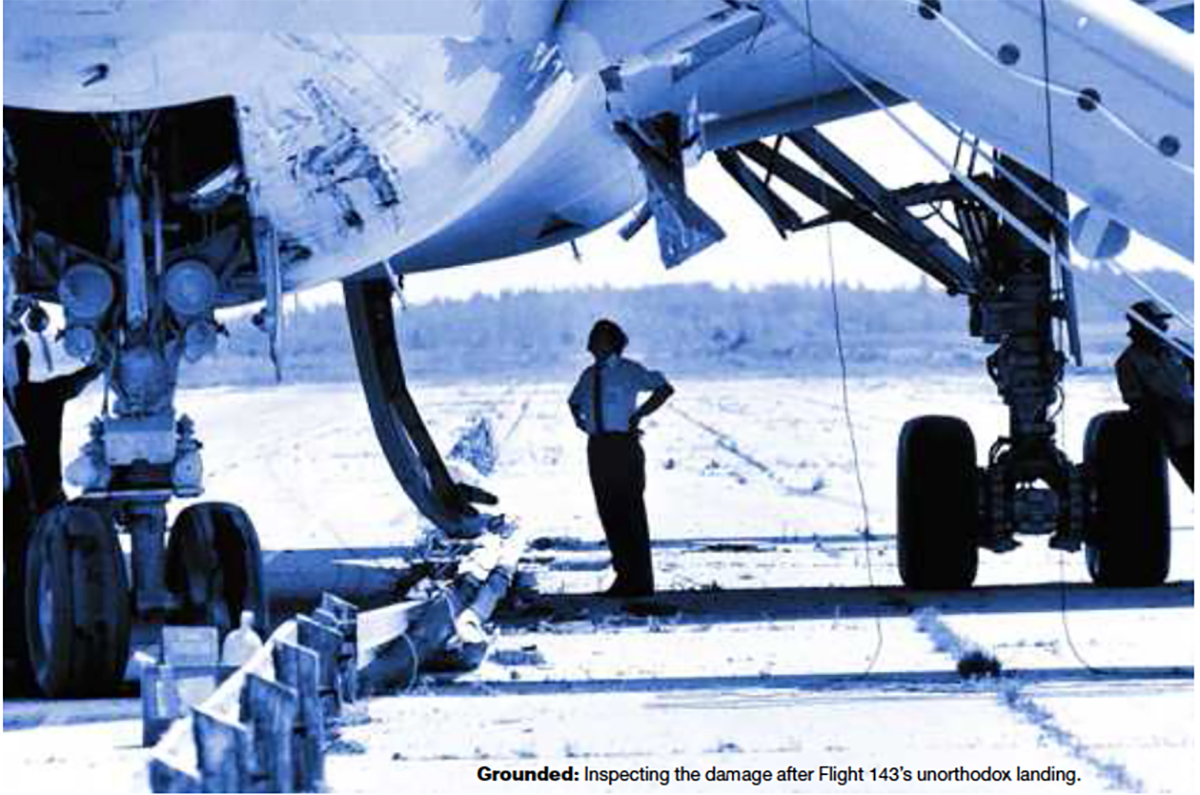

Accident Case Study: Air Canada 143

The captain of this airplane did a magnificent job dead sticking a Boeing 767 to a landing on an abandoned airfield. The first officer did a great job of computing glide ratios and keeping the captain informed. In fact, the performance of this crew in Cockpit Resource Management and Situational Awareness was superb from the moment they suspected they were out of fuel, all the way through the successful emergency landing, passenger evacuation, and aircraft fire fighting. Excellent.

The problem is that both pilots were instrumental to the fact the airplane took off without enough fuel.

More about this: Case Study: Air Canada 143

TLAR

There are a lot of good techniques out there for how to spot a gross fuel load error, but you should employ at least one. In my first jet, the mighty T-37B, it was easy. You always took off with full tanks. In long range jets? Not so easy. I remember my first flight in the Gulfstream GV going to Europe from New Hampshire. I was alarmed to see the fuel gauges were only halfway full. "Why so little fuel?" I thought. "Because that's all we need." That's when I started employing this technique. I'll use the G450 as an example:

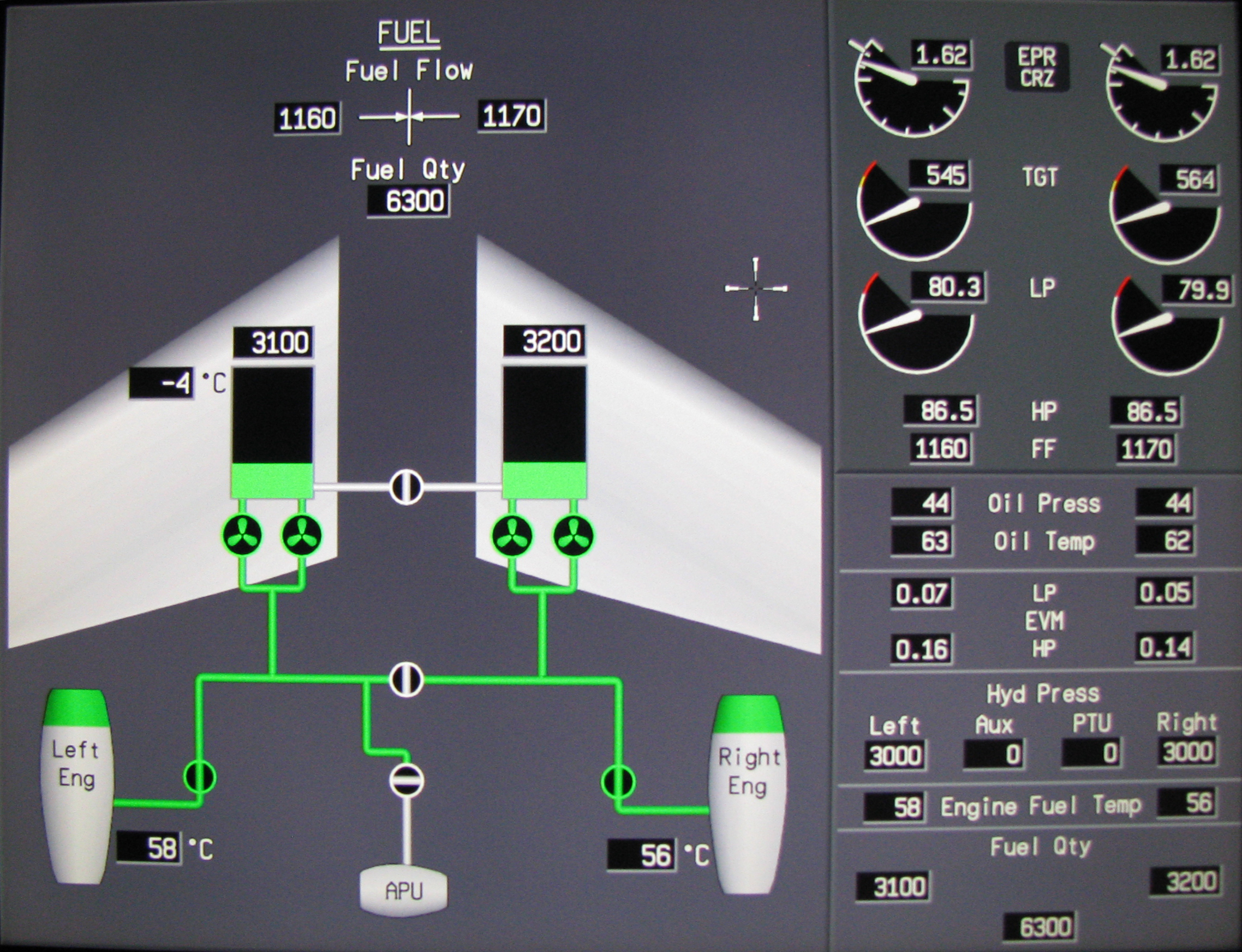

The Gulfstream G450 fuel system is an exercise in simplicity: two fuel tanks, one per engine. The aircraft can fly for ten hours and with both tanks full it can carry 29,500 lbs of gas. So — very rough approximation here — with the gauges full I can fly ten hours, half full: five hours, one-quarter full: 2 hours, 30 minutes.

The case study Boeing 767 had inoperative fuel gauges and more than a bit of poor math. I think that if I were in that situation, I would have asked to witness the fuel measuring sticks in use and come up with a fraction of the stick as a gauge. (As well as check the math!)

Finding Your TLAR

I think you should find the easiest to view fuel gauge, especially if it has a graphical representation like the G450 gauge shown. Take your longest duration flight and hack that into fractions to determine how full those gauges to take you half your duration, a quarter, and so on. If you don't have a graphical representation, do the same with the approximate fuel value.

3

Takeoff acceleration

I remember a few times as a copilot in the KC-135A loaded to maximum gross weight in very hot conditions going through the routine. The aircraft commander would command "brakes," and we would both press our brake pedals until our legs ached. He would advance the throttles to their "dry" (unaugmented) limit and say, "Start the water." I would reach down to the Water injection control panel and flip the switch to "start". We would watch to ensure all four engine pressure ratio gauges indicated our 9,000 lbs of thrust had indeed shot up to 12,000 lbs and then he would say, "Release brakes, three, two, one, now." Then we would both pop our feet off the brake pedals as quickly as possible and . . . wait. It usually took a second or two for the 300,000 aircraft to start moving. I once started rocking in my seat, as if trying to help the airplane get moving. "Not funny," the boss said.

Two aircraft in my history had takeoff acceleration checks (the T-38A and KC-135A) until they gave up on that as unnecessary. I'm not so sure. But I am sure you should have a good idea of what normal acceleration "feels" like so as to know when things aren't normal. There is a rhythm to it that doesn't sound scientific, but the rhythm of music really does have science behind it. You can apply science to your takeoff acceleration too.

Accident Case Study: Air Florida 90

The captain of this Boeing had lots of experience but not a lot of sense when it came to deice/anti-ice procedures and not enough real TLAR to understand his aircraft wasn't accelerating correctly. His first officer understood there was a problem, but deferred to the captain.

An airline pilot is at a disadvantage here. The grossweight of their aircraft can vary wildly and the acceleration during takeoff can vary as well. But hacking a timer at brake release and checking the time at your intermediate speed callout can improve our TLAR greatly.

More about this: Case Study: Air Florida 90

TLAR

Things happen quickly during takeoff for most corporate jets, except when fully loaded with fuel on a hot day. In our G450 I've managed to capture several data points with some reliability. There is a lot of variability in pilot technique, of course. But generally speaking, I've found:

- Light Weight: 8 to 12 seconds (brake release to 80 knots)

- Heavy Weight: 15 to 18 seconds (brake release to 80 knots)

If I find myself on a runway where the margin for error is small (at or near a balanced field), I will hack the clock at brake release, brief what I expect to see at 80 knots, give it a look at that speed, and consider what happens next. Because of the variability in pilot technique, the margin for error is large. If I am heavy and get to 80 knots in 20 seconds I am probably okay. But what about 30 seconds? Probably not. I've never had to abort for poor acceleration so I can't say how reliable this method is. But I think (hope) it will catch a dragging brake or gross error in our weight and balance.

Another technique is to see how much runway you have consumed at the speed point. For us, we almost always get to the 1,000 fixed distance marker around 80 knots, certainly by the next marker, indicating 1,500 feet.

Finding Your TLAR

You can buy a GoPro camera with a suction cup mount for around $100 these days and end up with some good footage of what happens and when during your takeoff roll. For more about this technique, see: Top Gun Debrief.

The idea is to record several takeoffs at light and heavy weights, then take an average. Use a timer or look at the video time to get an idea of how many seconds it takes to get to your intermediate speed callout, such as 80 knots. If you find yourself in a balanced field situation, brief what you expect for a time at that speed and look at your timer at that point.

4

Cabin pressure

We train to learn how to deal with an explosive depressurization and feel confident we can survive such a rare event. Evidence supports us. But these events are rare. We fail to train for gradual pressurization leaks or failure to pressurize after takeoff, because it would be hard (and time consuming) to simulate these. But there is evidence that slow onset hypoxia kills and rapid depressurization doesn't.

I've had one rapid and explosive depressurization at an altitude where it mattered (35,000 feet) and one where it was nonevent (around 15,000 feet). I've never had a failure to pressurize or a slow pressure loss. But I am paranoid about it. Here is my technique.

Accident Case Study: Learjet 35, N47BA

In many Slow Onset Hypoxia aircraft accidents, the exact cause is often shrouded in mystery because the aircraft is destroyed to the point where the evidence is unavailable. In this accident, "the aircraft failed to pressurize or lost pressurization for unknown reasons." Regardless of the reason, these pilots could have survived had they known what bit of TLAR was important before it was too late.

More about this: Case Study: Learjet 35, N47BA

TLAR

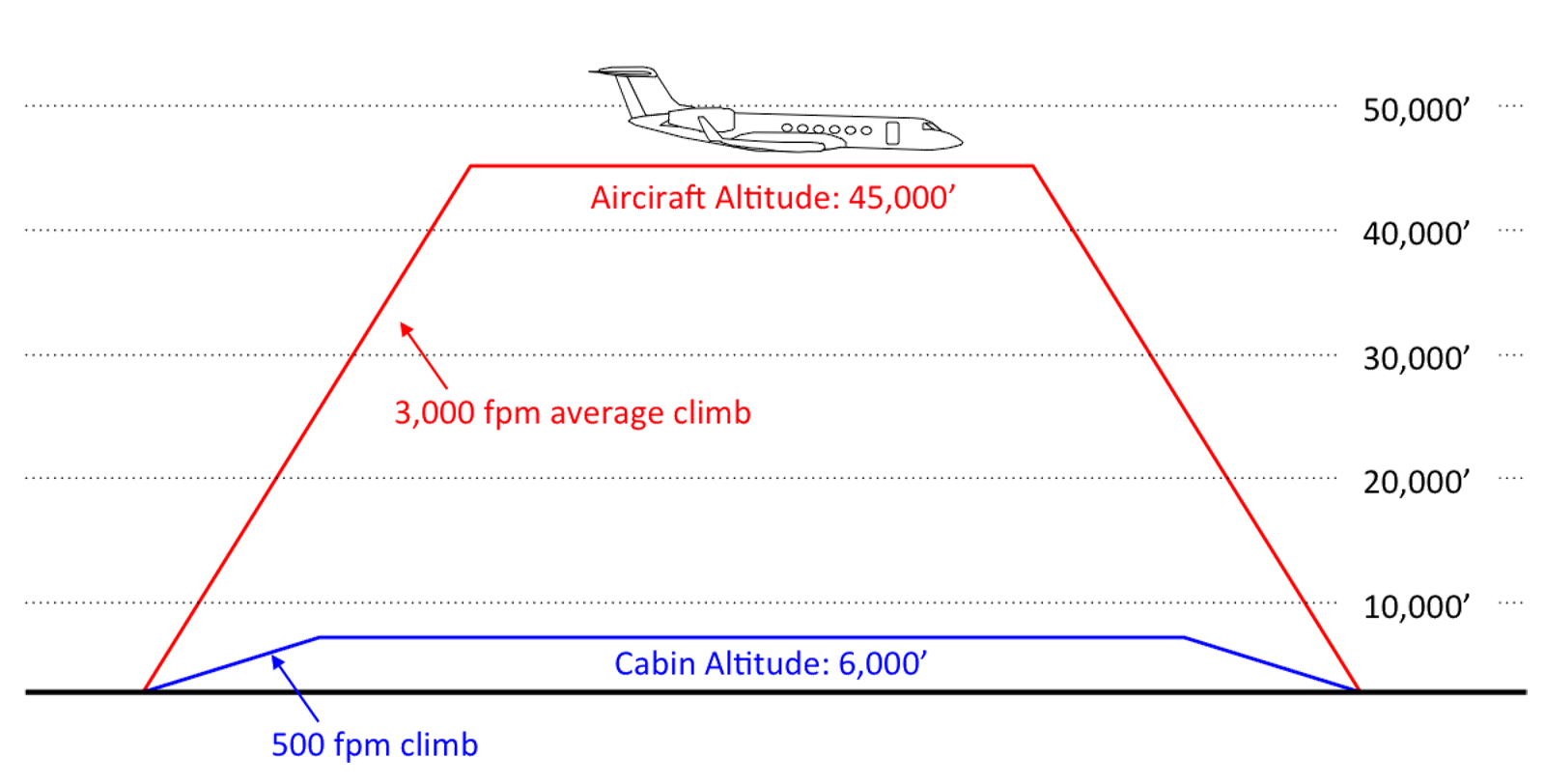

This technique is very easy and becomes automatic if you let it. First, you need a checklist item that requires you to check pressurization at 10,000 feet. Chances are good that you already have that. But chances are equally good that you are doing it all wrong.

The common response to the checklist item "Pressurization" is "Check." Some people will respond with the differential pressure. "3.6 Delta P." These responses are just about useless. A second problem is timing. When do you make the check? Too early means you haven't given enough time to allow a true differential to develop. Too late and you may already be hypoxic and on your way to being mentally incapacitated.

When. We make this check at 10,000 feet aircraft altitude. We know that if the airplane hasn't pressurized, we can survive and think at this altitude.

What. We check the cabin pressure altitude, not the Delta P.

How. We announce it. "Cabin altitude, 1,000 feet."

Why. If you do this for every flight, sooner or later you will get a feel for what is normal on your airplane. I'll tell you what is normal for us, but first, a quiz.

Why not. Announcing the differential pressure means very little to us. We might know the maximum Delta P for our aircraft, perhaps it is 8. But what does a Delta P of 3 means at 10,000 feet? Is that good? But if you see a cabin altitude of 5,000 feet when crossing an aircraft altitude of 10,000 feet, you know something isn't right.

Finding Your TLAR

If you are taking off from your home airport and climbing up to a higher altitude, say in the thirties or forties, what do you expect your cabin pressure will be passing 10,000 feet aircraft altitude? Write that down. Now hop in your airplane and give it a shot.

I am betting the answer is lower than you expected. Most jet aircraft will default to a 500 feet per minute climb in the cabin pressure until reaching a target Delta P. So if your aircraft can climb at 4,000 feet per minute from sea level to 10,000 feet, it will only take you 2 minutes 30 seconds. That means our cabin altitude will only be 2,000 feet. But your climb rate isn't linear and chances are it will be even lower.

For our Gulfstream G450, we rarely see more than 1,000 feet cabin altitude when passing 10,000 feet aircraft altitude. If you announce the cabin altitude whenever climbing through 10,000 aircraft altitude, sooner or later you will have the TLAR needed to prevent never figuring out your airplane has failed to pressurize.

5

Takeoff, cruise, go around pitch

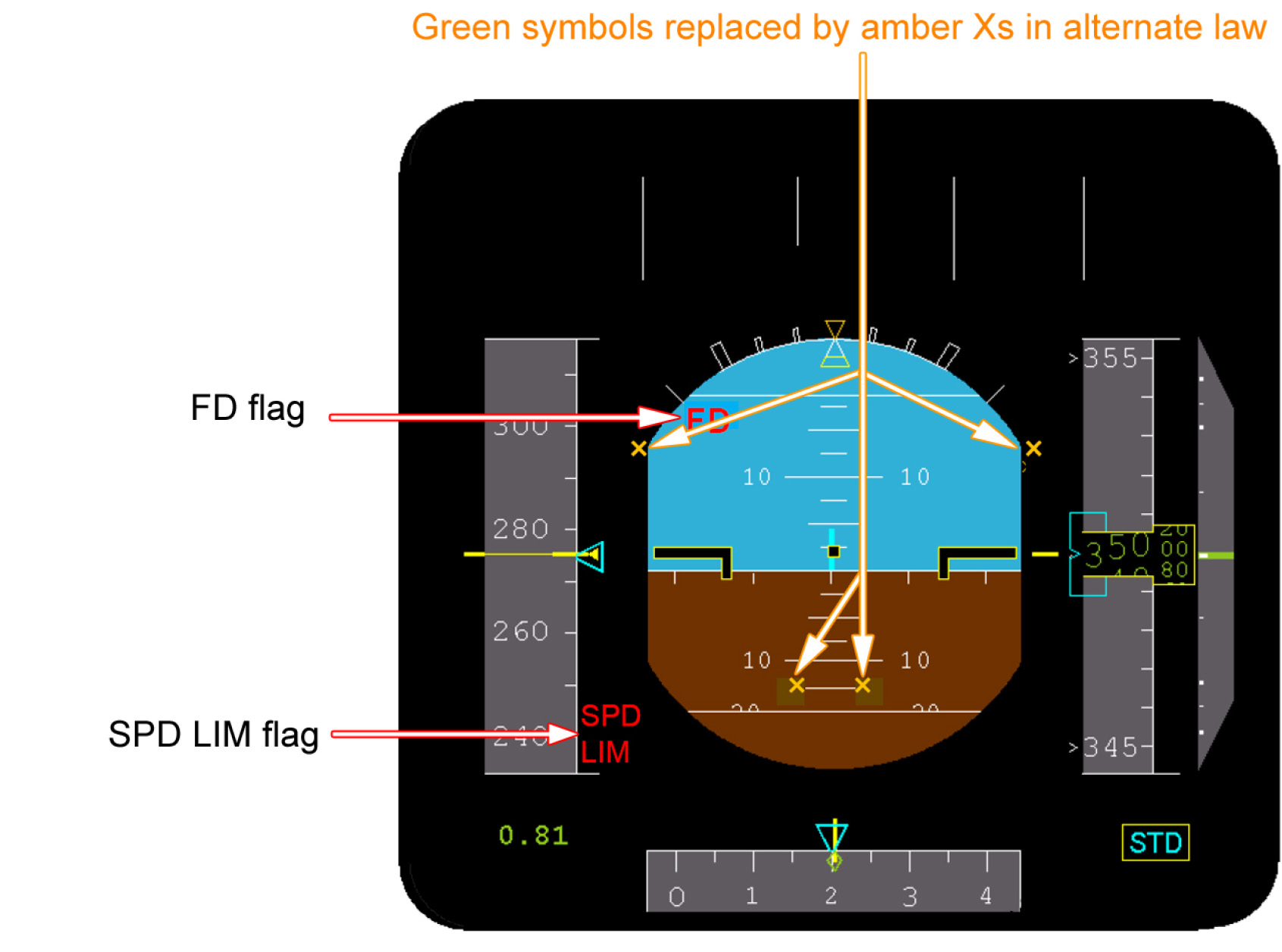

Most transport category aircraft will have a primary, a secondary, and a standby pitot-static system because having reliable airspeed is critical. In the years after Aero Peru 603, we've added techniques like using our GPS for altitude while converting GPS speed into groundspeed, then true airspeed, and then to some semblance of calibrated (or indicated) airspeed. So the impact of a triple failure can be mitigated. So what happened in the case of Air France 447?

You should have memorized a "fail safe" pitch for your aircraft under just about any condition. You can make it easier: what pitch setting guarantees you will climb away from the terrain at full power, even with an engine failure, following takeoff or a low altitude go around? Now ask the same question for the aircraft at high altitude. Memorize these.

Accident Case Study: Air France 447

The real tragedy of Air France 447 is that had any pilot with more experience hand flying at high altitudes been at the controls, the aircraft could have survived. Had the pilots in the seats simply kept the thrust set to where it was and the nose just a few degrees above the horizon, the problem would have corrected itself in about a minute. But these pilots didn't have the necessary TLAR.

More about this: Case Study: Air France 447

TLAR

I've been using this technique for decades, but it started out as this: "When in doubt, full thrust at ten degrees." That would always get the airplane pointing away from the rocks, even with an engine out. But as I started flying over-powered airplanes, I needed to raise that pitch to 15 degrees. And then I realized that won't work at altitude. For my current aircraft, 3 degrees nose up works for just about any altitude above 30,000 feet.

Finding Your TLAR

Of course your aircraft may be different.

I recommend you start noticing these things in the simulator (for the low altitude stuff) and the airplane (for the high altitude.) You will also need to give the simulator a try at high altitude with an engine failed.

References

(Source material)

Final Report on the Accident on 1st June 2009 to the Airbus A330-203 registered F-GZCP operated by Air France flight AF 447 Rio de Janeiro - Paris, Bureau d'Enquêtes et d'Analyses (BEA) pour la sécurité de l’aviation civile, Published July 2012.

Flight Safety Australia, The 156-tonne Gimli Glider, July-August 2003